Reactive Ion Etching

RIE Sentech Plasma System SI 500

The RIE system with Inductively Coupled Plasma features a Planar Triple Spiral Antenna (PTSA), which enhances plasma uniformity and etching precision. It includes a dynamic temperature control system for the substrate, ensuring optimal etching conditions and improved material processing. Additionally, the system is equipped with an endpoint detector that monitors the etching process in real-time, allowing for precise control and improved etching accuracy.

Sample size

Up to 150mm

Gases

Ar, C4F8, CHF3, Cl2, HBr, O2, SF6

Power

RF bias: 600W, ICP: 1200W

Allowed materials

Si, SiO2, SiN and 2D materials (hBN, graphene, TMD)

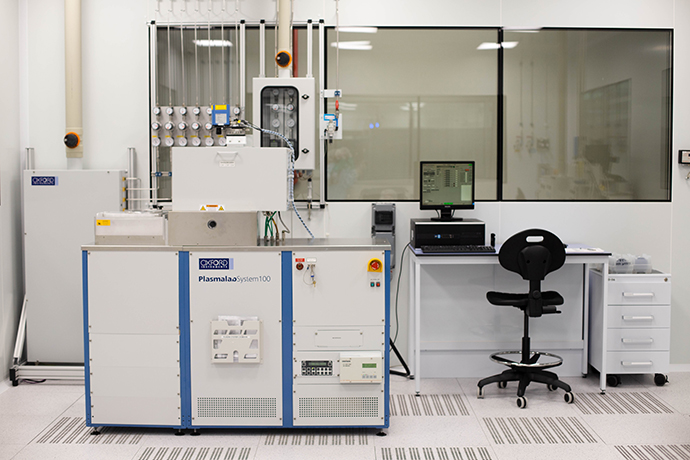

RIE Oxford Instruments Plasmalab System 100 ICP 180

This Reactive Ion Etching system with Inductively Coupled Plasma (ICP) technology offers precise etching for microfabrication applications. It uses reactive gases and plasma to achieve high etching rates and excellent selectivity, enabling intricate structures with high aspect ratios. The ICP capability ensures uniform plasma distribution, enhancing process control and efficiency.

Sample size

Up to 100mm

Gases

Ar, C4F8, CHF3, Cl2, HBr, O2, SF6

Power

RF bias: 600W, ICP: 2000W

Allowed materials

Metals, AlOx, glass and samples with metal masks

RIE SAMCO 10N

The RIE-10NR is a high-performance, fully automatic Reactive Ion Etching system using fluorine chemistry for selective anisotropic etching. It delivers precise etching with minimal sidewall deterioration and high selectivity between materials, making it ideal for advanced process requirement

Sample size

Up to 200mm

Gases

Ar, CHF3, O2, SF6

Power

RF bias 300W

Allowed materials

Si, SiO2, SiN, 2D materials, metals, AlOx, glass, PbS, InSb, InAs, ITO